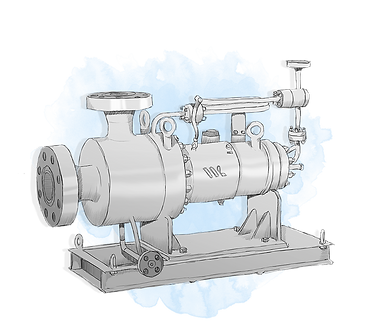

CANNED MOTOR

CMP SERIES

Used for aggressive, inflammable, explosive, toxic or valuable liquids and liquified gases; when leakage is not an option. Canned Motor Pumps are a combination of centrifugal pumps with a 3-phase induction motors. The impeller and rotor are installed on a single shaft. The stator liner, or so called "can", separates the stator chamber from the wet rotor chamber.

The design is without a shaft seal and therefore free of leakage. The pumping liquid cools and lubricates the slide bearings and the rotor chamber. The secondary pressure containment, which is achived by the stator shell, provides the safety level for personnel and the environment.

MAIN APPLICATIONS

-

Hazardous Chemicals.

-

Petrochemical - oil refining.

-

Liquified Gases.

-

Reverse osmosis.

-

Utilities: air conditioning and boiler circulation.

-

High melting temperature liquids.

MAIN FEATURES

-

Leakproff design.

-

Airtight and compact design.

-

No dynamic shaft seals.

-

Explosion Proof.

-

Quiet operation. Low noise and low vibration.

-

High weather and dust resistance.

-

No external lubrication needed.

-

Design flexibility according to the application requirements: self-priming, slurries, high temperature, high pressure, reverse circulation, etc.

MAIN BENEFITS

-

Integrated pump and motor ensures environmental protection and on-site safety.

-

Low life cycle cost.

-

Reduced installation costs; alignement of motor and pump is not necessary.

-

Compact integrated design, less space required.

-

Easy of maintenance. Field repairable.

ENVELOPE

Capacity

Heads

Pressure

Temperature

3430 GPM (780 m3/hr)

530 feet (160 m)

300 PSIG (200 bar)

842 F (450 C)